Perovskite/silicon tandem solar cells have become a research hotspot in the photovoltaic field because of their theoretical efficiency exceeding 40%. However, the optical loss of transparent electrodes (such as reflection and parasitic absorption) severely limits the improvement of short-circuit current density JSC. Traditional single-layer transparent conductive oxides (TCOs) such as IZO (zinc-doped indium oxide) and IZrO (zirconium-doped indium oxide) have problems such as low crystallinity and insufficient carrier mobility.

This study designed IZrO/IZO multilayer films, combined with gradient refractive index anti-reflection strategies, and used the Meineng perovskite film thickness tester to monitor the film deposition process in real time, optimize electrode performance, and ultimately promote the efficiency of tandem cells to exceed 30%.

Thickness optimization of IZrO/IZO multilayer films

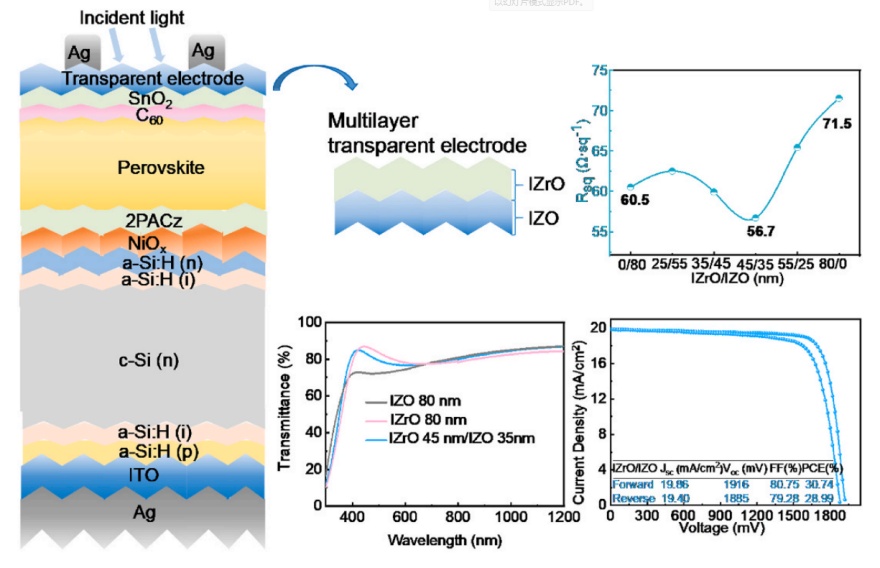

Schematic diagram of the structure of the full-texture P-I-N type perovskite/silicon tandem cell

The research team used radio frequency magnetron sputtering technology to alternately deposit IZrO and IZO layers on a glass substrate with a total thickness of 80 nm. The key process parameters are as follows:

IZO layer: sputtering pressure 1.5 mTorr, power density 2.2 W/cm², oxygen partial pressure 3%;

IZrO layer: sputtering pressure 0.9 mTorr, power density 3.1 W/cm², oxygen partial pressure 0.06%.

The crystallinity and optoelectronic properties of the film are optimized by adjusting the thickness ratio (such as IZrO:IZO = 45:35 nm). XRD analysis shows that the multilayer film presents a (222) and (400) dual-oriented structure, with a grain size of 50–70 nm, which significantly reduces grain boundary scattering.

Preparation process of perovskite/silicon tandem cell

Bottom cell processing: 20 nm ITO is deposited on the textured silicon heterojunction (SHJ) bottom cell as a tunnel junction;

Hole transport layer: 30 nm NiOx is sputtered and a 2PACz self-assembled monolayer (SAM) is introduced;

Perovskite absorber layer: perovskite film is deposited by solution method;

Electron transport layer: 15 nm GeO is evaporated and 20 nm SnO₂ is atomically deposited (ALD);

Transparent electrode integration: sputtered IZrO/IZO multilayer film (45/35 nm) is used as the top electrode;

Metal electrode: Ag grid line is thermally evaporated, and the active area is calibrated to 1.05 cm².

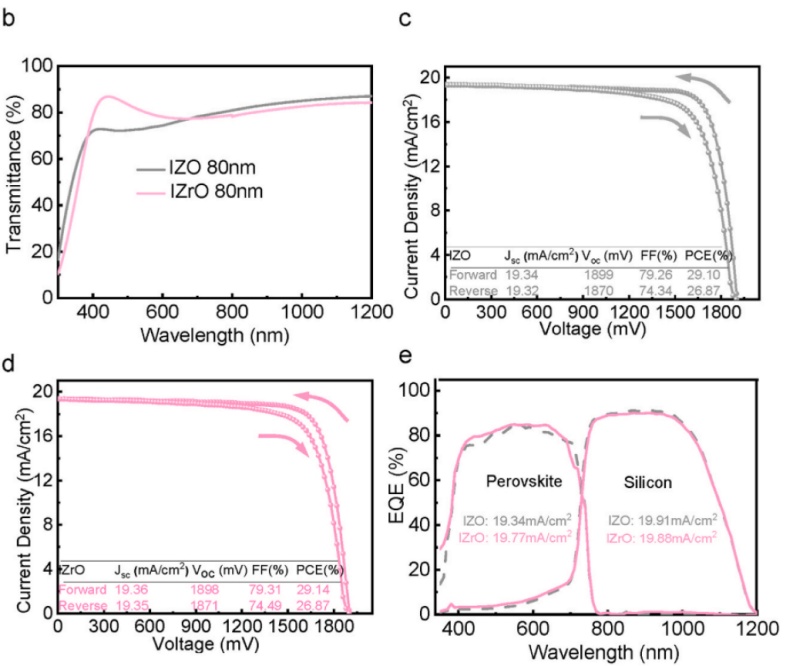

Performance defects of single-layer film

(b) Comparison of optical transmittance of IZO and IZrO single-layer films; (c) J-V curve of stacked cells with single-layer IZO transparent electrodes; (d) J-V curve of stacked cells with single-layer IZrO transparent electrodes; (e) EQE spectra of champion cells using single-layer IZO and IZrO transparent electrodes

Optical performance:

The average transmittance of IZO in the visible light region (400–800 nm) is 80.05%, and the transmittance in the near-infrared region (800–1200 nm) is slightly lower;

The transmittance of IZrO in the visible light region reaches 81.25%, but the transmittance in the near-infrared region is insufficient.

Electrical bottleneck:

IZO has low carrier mobility due to its amorphous structure, with a sheet resistance of 60.5 Ω·sq⁻¹;

IZrO has a low carrier concentration (n = 4.81 u×1020cm-3), with a sheet resistance of 71.5 Ω·sq⁻¹.

cell performance:

The open circuit voltage (VOC < 1900 mV) and fill factor (FF < 79.4%) of single-layer electrode cells are limited, and the PCE does not exceed 29.5%.

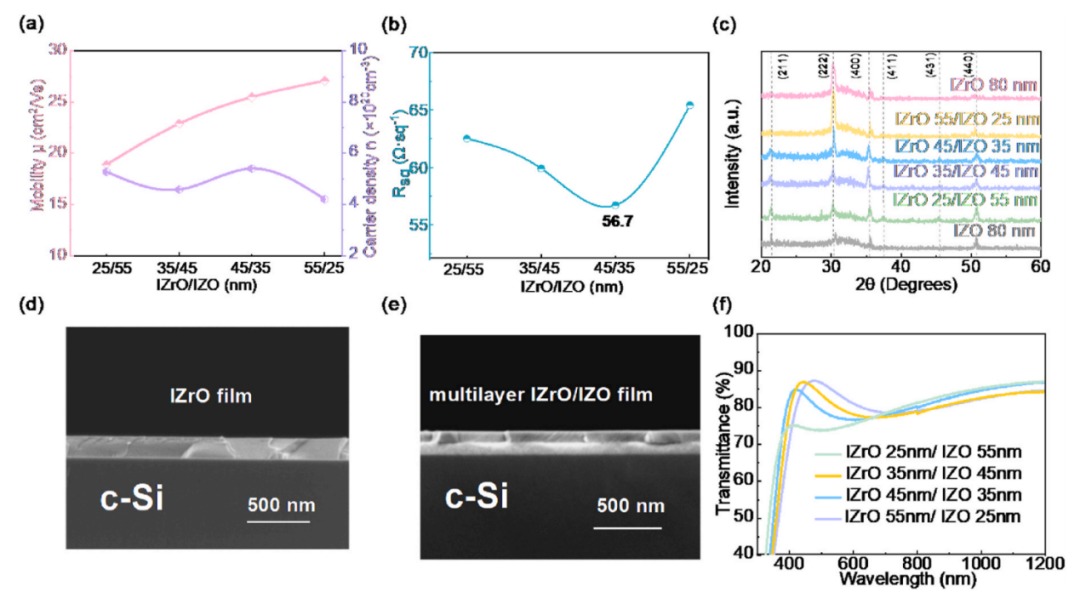

Multilayer film performance optimization

Crystallization characteristics and photoelectric properties of IZrO/IZO multilayer films

(a) Carrier mobility, sheet resistance and carrier concentration; (b) Sheet resistance; (c) XRD pattern; (d) Cross-sectional SEM image of IZrO single-layer film; (e) Cross-sectional SEM image of IZrO/IZO multilayer film; (f) Comparison of optical transmittance of IZrO/IZO multilayer film

(a) Carrier mobility, sheet resistance and carrier concentration; (b) Sheet resistance; (c) XRD pattern; (d) Cross-sectional SEM image of IZrO single-layer film; (e) Cross-sectional SEM image of IZrO/IZO multilayer film; (f) Comparison of optical transmittance of IZrO/IZO multilayer film

The optimized multilayer film (45/35 nm) performs as follows:

Electrical properties: carrier mobility, sheet resistance Rsq = 56.7 Ω·sq⁻¹, better than single-layer film;

Improved crystallinity: The dual-oriented structure reduces grain boundary scattering, and the grain size increases to 50–70 nm.

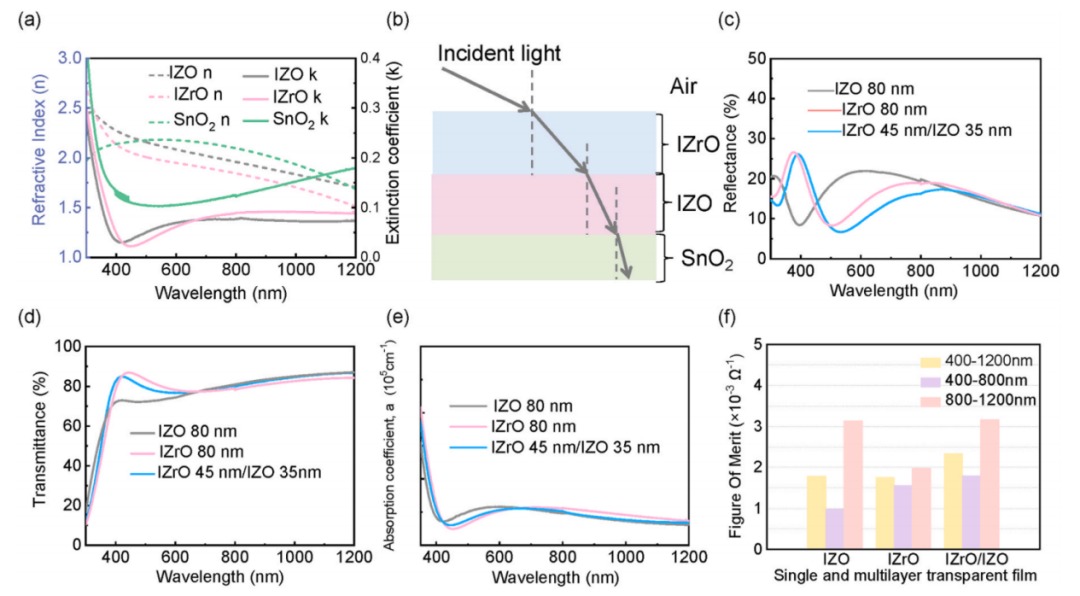

The effect of gradient refractive index on reflectivity and parasitic absorption

(a) Refractive index and extinction coefficient of IZO film, IZrO single-layer film and SnO₂ buffer layer; (b) Incident light path diagram of stacked cells with IZrO/IZO multilayer transparent electrodes; (c) Optical reflectivity comparison; (d) Optical transmittance comparison; (e) Optical absorption coefficient comparison; (f) Quality factor comparison of IZO, IZrO single-layer film and IZrO/IZO multilayer film

Gradient refractive index design: IZrO (n ≈ 1.9), IZO (n ≈ 1.8) and SnO₂ buffer layer (n ≈ 1.6) form a continuous refractive index gradient, and the reflectivity is 3.11% lower than that of the single-layer film;

Transmittance advantage: The average transmittance of the entire band reaches 81.68%, and the parasitic absorption coefficient is reduced by 10–15%.

Different thickness ratios have a significant impact on film performance

IZrO:IZO = 30:50 nm: the film surface roughness increases (RMS > 5 nm), causing the transmittance to drop to 78.3%;

IZrO:IZO = 50:30 nm: insufficient transmittance in the near-infrared region (800–1200 nm average transmittance 76.2%);

Optimal ratio 45:35 nm: average transmittance across the entire band reaches 81.68%, surface roughness drops to 3.2 nm (AFM test), and the grain size is uniform (50–70 nm).

Improved performance of stacked cells

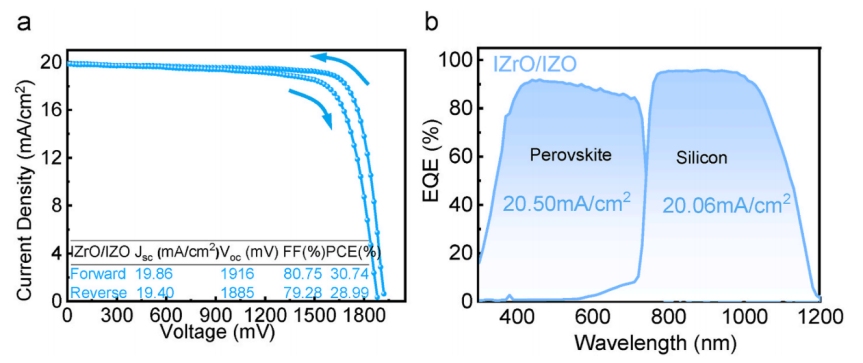

Photovoltaic performance of champion cell (a) J-V curve shows efficiency of 30.74%; (b) EQE spectrum shows current matching between top and bottom cells

Key indicators of stacked cells using IZrO/IZO multilayer electrodes:

JSC: 19.86 mA/cm² (EQE integrated current matching > 99%);

VOC: 1916 mV (low resistance reduces voltage loss);

FF: 80.75% (energy level matching reduces non-radiative recombination);

PCE: 30.74% (one of the highest efficiencies of sputtered TCO electrodes at room temperature).

This study significantly improved the photoelectric performance of transparent electrodes through IZrO/IZO multilayer film design, combined with lattice optimization and gradient refractive index strategy. The efficiency of stacked cells exceeded 30%, verifying the industrialization potential of the electrode.