As global energy demand grows, solar cell technology has developed rapidly and has become an important part of renewable energy. It is expected that by 2029, the solar panel market will exceed 700GW. This paper explores the impact of screen printing technology on the morphology of silver paste printing, especially the impact of different ways of mesh overlap on the height and cross-sectional area of the grid line. Experiments show that no mesh overlap can reduce the height fluctuation of the grid line and increase the cross-sectional area, thereby reducing resistance and improving the conversion efficiency of solar cells, while reducing the consumption of silver paste and reducing costs.

Refinement of screen wire diameter

The grid lines printed on the surface of the solar cell will block part of the area, reduce photon absorption, and thus reduce the photoelectric conversion efficiency. Therefore, in order to reduce the shading area, the grid lines need to be designed to be as thin as possible while maintaining sufficient conductivity.

2022: The mainstream mesh wire diameter on the Chinese market is 11μm, and the grid line printing width is 23μm.

2023: Through the etching process, the mesh wire diameter is reduced from 11μm to 9μm, and the grid line printing width is also reduced from 23μm to 20μm. This improvement has increased the conversion efficiency of the single-cell solar cell by more than 0.05%, while reducing the silver paste consumption by more than 10%.

Potential challenges of no-grid technology

The influence of grid line undulation height

Excessive undulation on the surface of the grid line will lead to waste of silver paste and increase production costs. Reducing the grid line undulation height can reduce the use of silver paste, thereby reducing costs.

At present, the average height fluctuation of printing is 6μm. If the average height fluctuation can be reduced to 4μm, the consumption of silver paste will be reduced by 12.5%.

Influence of cross-sectional area

In the screen printing technology of solar cells, the cross-sectional area of the grid line is a key parameter, which directly affects the electrical performance and production cost of the solar cell. Resistance formula: (R is resistance, p is resistivity, A is cross-sectional area)

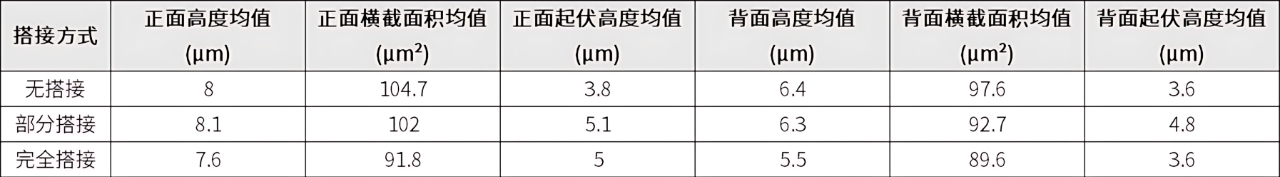

The larger the cross-sectional area, the smaller the resistance. Therefore, increasing the cross-sectional area of the gate line can effectively reduce resistance and reduce power loss, thereby improving the photoelectric conversion efficiency of solar cells. Experiment 1: The influence of the grid junction overlap method on the morphology

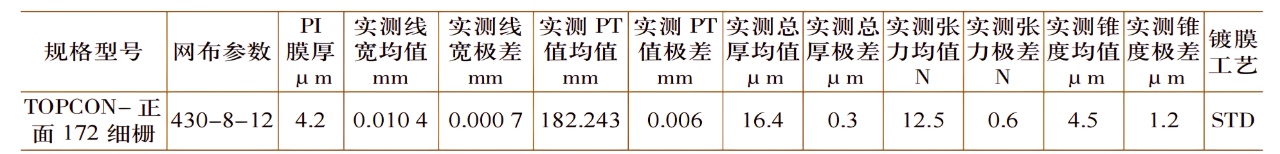

Use N-type front silver paste and N-type back silver paste to print on the front and back of the silicon wafer respectively. The front printing height requirement is 8~10μm, and the back printing height requirement is 4~5μm.

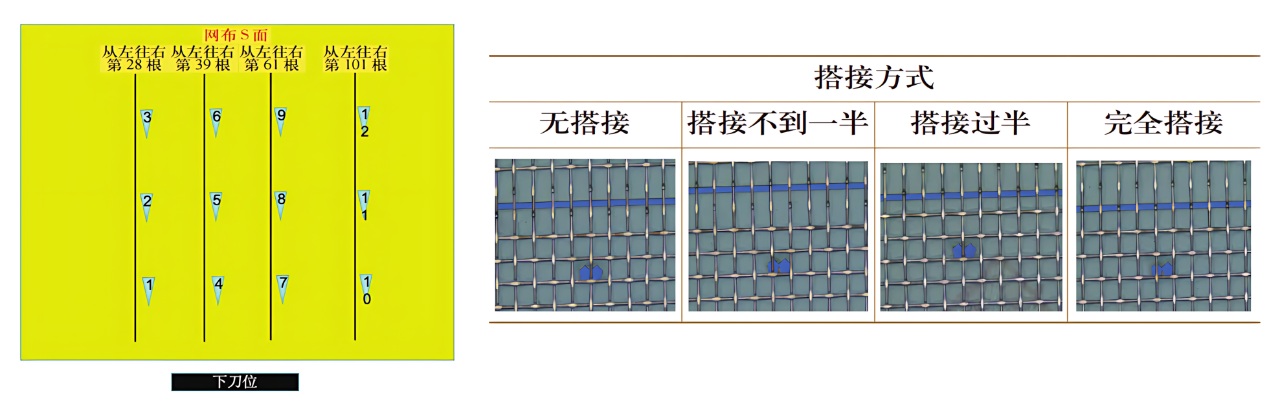

Take 12 positions with different degrees of overlap between the fine grid and the knots, and divide them into four categories:

No overlap: There is no intersection between the printed lines and the knots.

Less than half overlap: The knots cover part of the line, but not more than half of the line.

Overlap more than half: The knots cover part of the line, more than half of the line.

Complete overlap: The knots are completely between the lines.

Printing morphology with no overlap and partial overlap

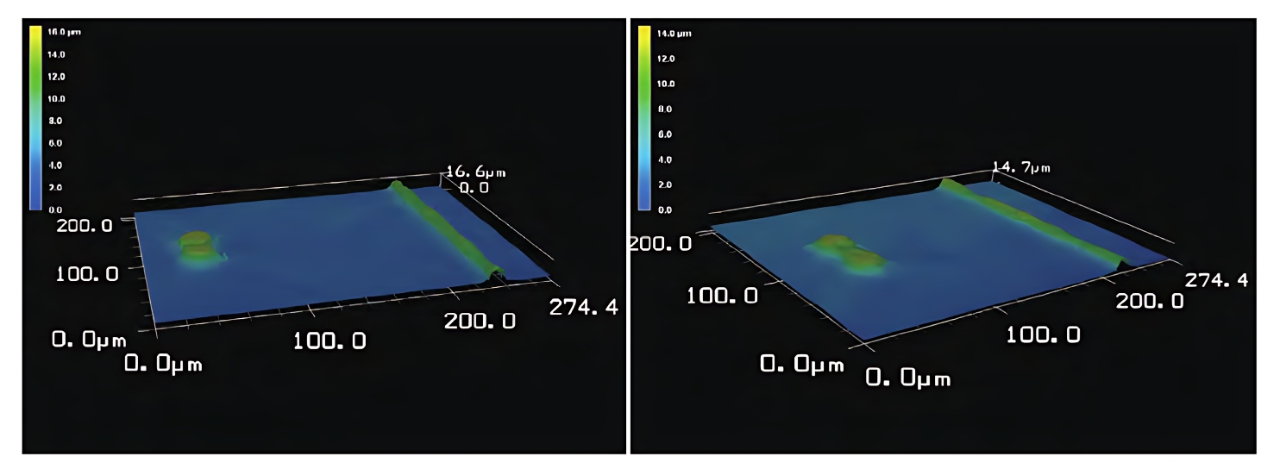

Knot-free overlap: It can significantly reduce the undulation height of the grid line and increase the cross-sectional area, thereby reducing resistance and improving the photoelectric conversion efficiency of solar cells. By reducing the undulation height of the grid line, the amount of silver paste used can be reduced, thereby reducing costs.

Knot-free overlap: It can significantly reduce the undulation height of the grid line and increase the cross-sectional area, thereby reducing resistance and improving the photoelectric conversion efficiency of solar cells. By reducing the undulation height of the grid line, the amount of silver paste used can be reduced, thereby reducing costs.

Through the data analysis of Experiment 1, it can be clearly seen that the knot-free overlap has significant advantages in reducing the undulation height of the grid line and increasing the cross-sectional area.

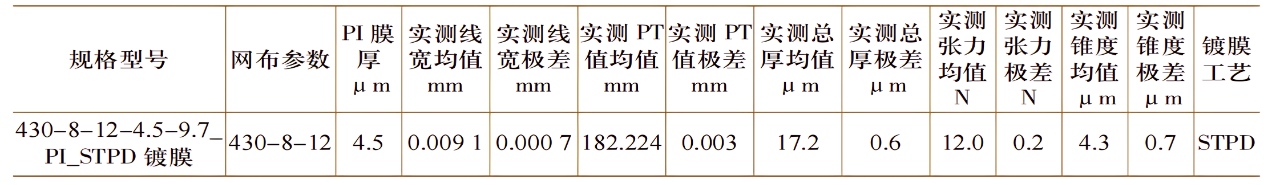

Experiment 2: Coordinated optimization of paste and printing parameters

Divided into two groups to study the effects of different printing parameters and different silver paste materials on the morphology of the grid line

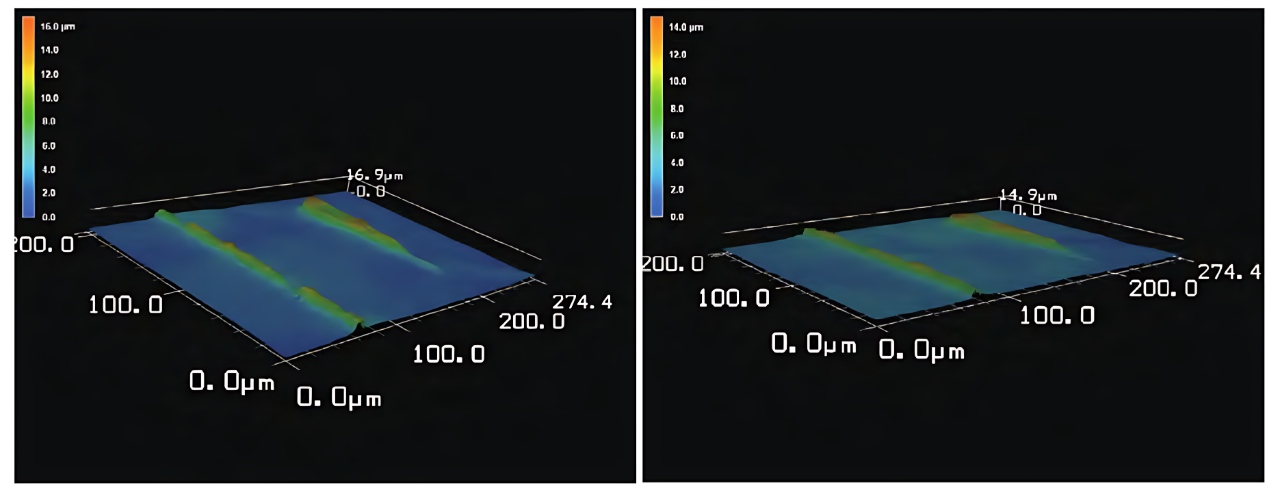

No overlap and partial overlap printing morphology under 300-800-1.2-50 printing conditions

No overlap and partial overlap printing morphology under 300-800-1.2-50 printing conditions

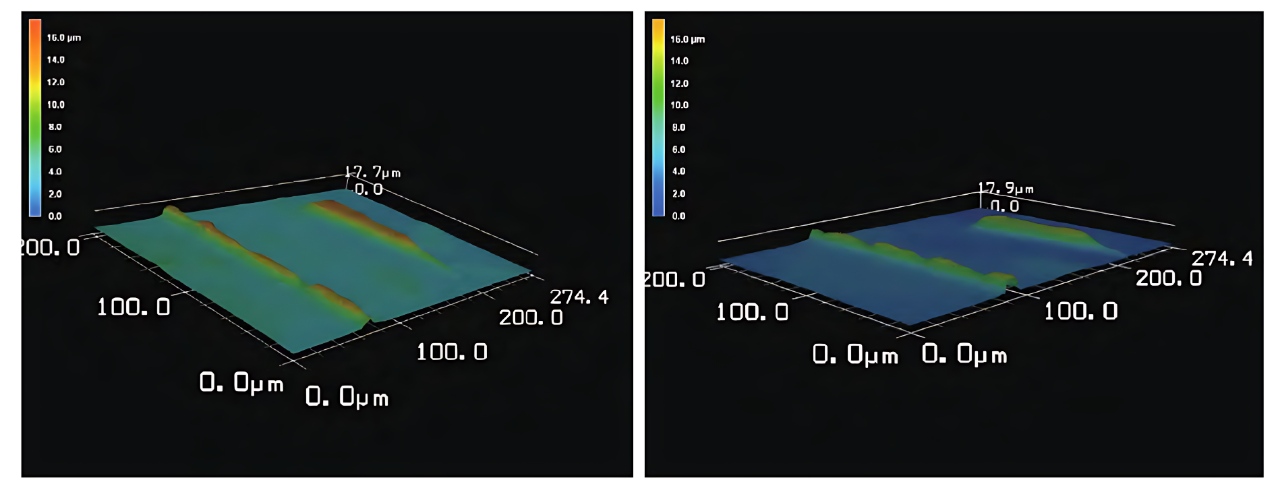

No overlap and partial overlap printing morphology under 500-1000-1.6-50 printing conditions

No overlap and partial overlap printing morphology under 500-1000-1.6-50 printing conditions

The surface of the grid line without mesh knot overlap is flat, which reduces light reflection and scattering and improves light absorption efficiency. The larger cross-sectional area reduces resistance and improves the photoelectric conversion efficiency of the solar cell. The smaller undulation height reduces the waste of silver paste and reduces production costs.

The surface of the partially overlapped grid line is more undulating, which leads to increased light reflection and scattering and reduces light absorption efficiency. The smaller cross-sectional area increases resistance and reduces the photoelectric conversion efficiency of the solar cell. The larger undulation height leads to waste of silver paste and increases production costs.

Through in-depth research on solar cell screen printing technology, especially the influence of different mesh knot overlap methods on the grid line printing morphology, the significant advantages of the mesh knot-free overlap technology in improving solar cell performance and reducing costs are revealed. Experimental results show that the mesh knot-free overlap can significantly reduce the undulation height of the grid line, increase the cross-sectional area, thereby reducing resistance and improving photoelectric conversion efficiency. In addition, by optimizing the screen design and printing process, the use of silver paste can be further reduced and the production cost can be reduced.