As a new generation of photovoltaic technology, the industrialization process of perovskite solar cells faces the key challenge of large-scale preparation quality control. This study proposes an innovative non-destructive characterization technology, k-parameter imaging (k-imaging), which analyzes the power law relationship of light intensity-dependent photoluminescence (PL) and realizes the rapid and accurate evaluation of perovskite film quality.

Light intensity-dependent photoluminescence PL imaging technology

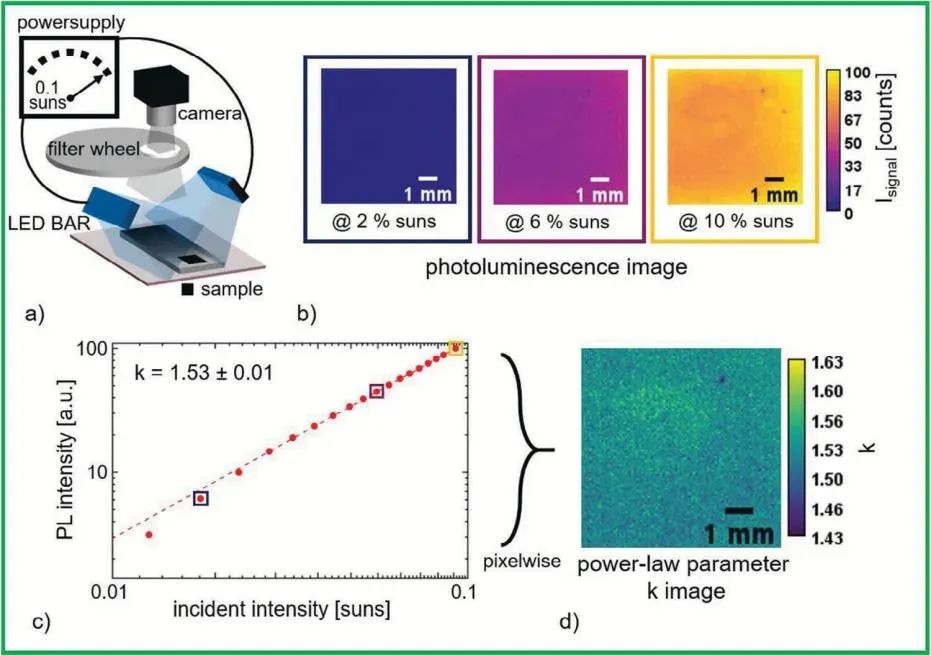

(a) Schematic diagram of the experimental device (b-c) PL intensity image and power law fitting (d) k parameter spatial distribution diagram

Physical connotation of k parameter

The study found that the PL intensity of perovskite film follows a power law relationship with the excitation light intensity, in which the index k has a clear physical meaning:

k→1: radiative recombination dominates (high quality)

k→2: defect-assisted non-radiative recombination is significant. Through the derivation of the rate equation, there is a quantitative relationship between the k value and the non-radiative recombination efficiency ηnr: ηnr≈(k-1)

Imaging system design The figure above shows the self-built optical system:

Excitation source: dual 467nm LED array, achieving <3% non-uniformity (135×75mm²)

Detection module: 715nm long-pass filter + sCMOS (70μm/pixel)

Multi-light intensity excitation: 18 levels of gradient (0.01-0.1suns), single measurement 5 minutes

The system obtains the k distribution map through pixel-level power law fitting. The standard sample test shows k=1.53±0.01, corresponding to non-radiative loss ~30%.

Anti-interference verification experiment

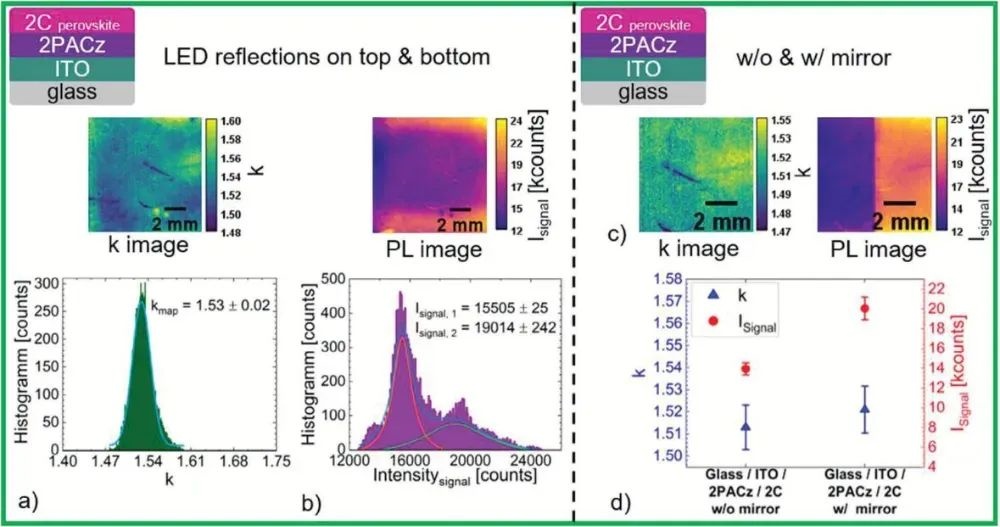

Anti-interference verification (a-b) non-uniform excitation contrast (c-d) mirror reflection interference experiment

To verify the immunity of k imaging technology to optical artifacts, the researchers designed two control experiments. In the non-uniform excitation experiment, a 23% light intensity enhancement was artificially created in the edge area. It was found that although the PL intensity showed a significant gradient change, the spatial distribution of the k parameter remained uniform. This phenomenon can be explained by the rate equation theory: the k parameter essentially reflects the proportional relationship of the recombination mechanism and is independent of the absolute light intensity.

The second experiment placed the sample part above the mirror. The results showed that the PL intensity in the mirror reflection area increased by 44%, while the k value difference was less than 1%. This result is of great significance: in traditional PL imaging, signal fluctuations caused by differences in substrate reflectivity are often misjudged as changes in film quality, while the k parameter effectively avoids this misdiagnosis risk. This is particularly important for the diverse substrate scenarios commonly seen in industrial applications.

Hole transport layer HTL interface diagnosis

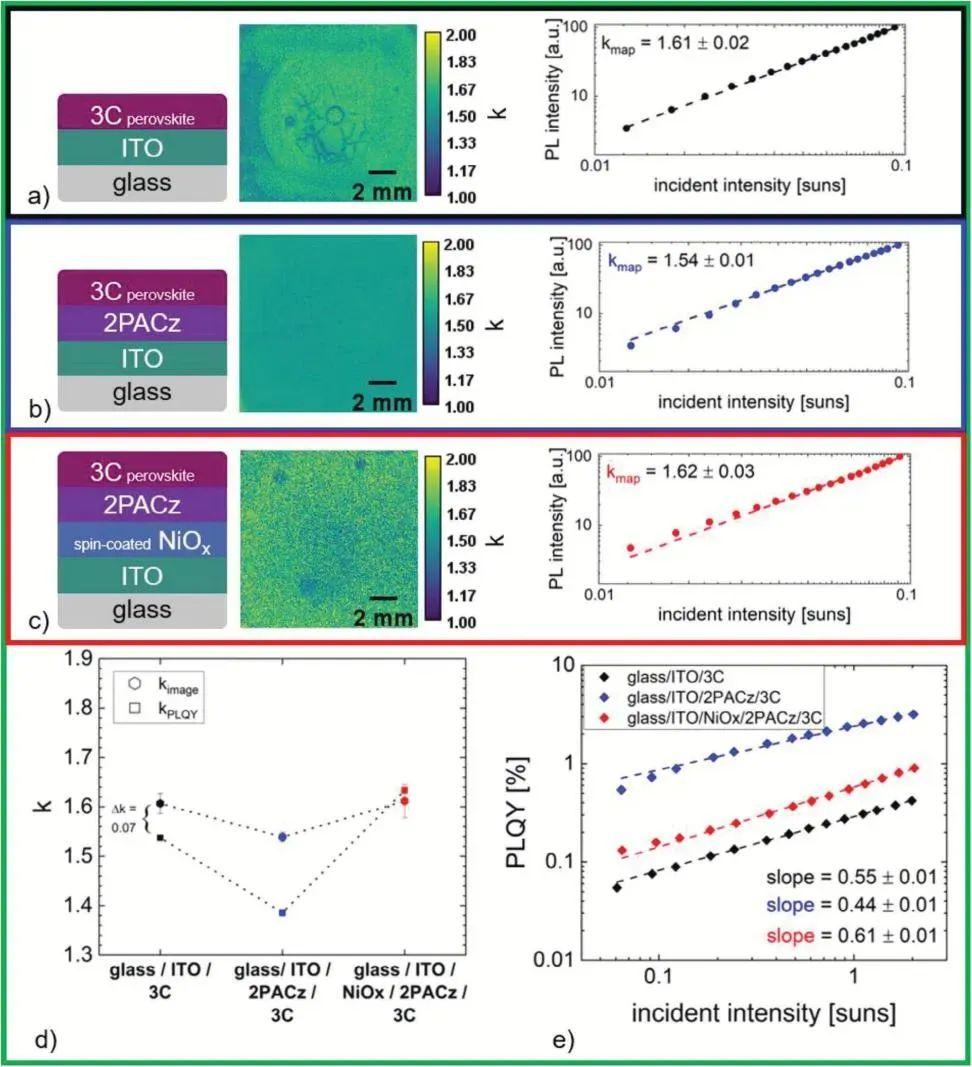

Interface engineering evaluation (a-c) k imaging of three hole transport layers (d-e) Integrating sphere verification

By comparing the effects of three hole transport structures on the quality of perovskite films. It is found that the k value is directly related to the interface defect density: the introduction of the 2PACz interface layer can reduce the k value (from 1.61 to 1.54), indicating that non-radiative recombination is reduced; while the spin-coated NiOx layer causes the k value to rise (1.62) due to surface defects, verifying the regulatory effect of interface engineering on the recombination process.

Passivation process optimization

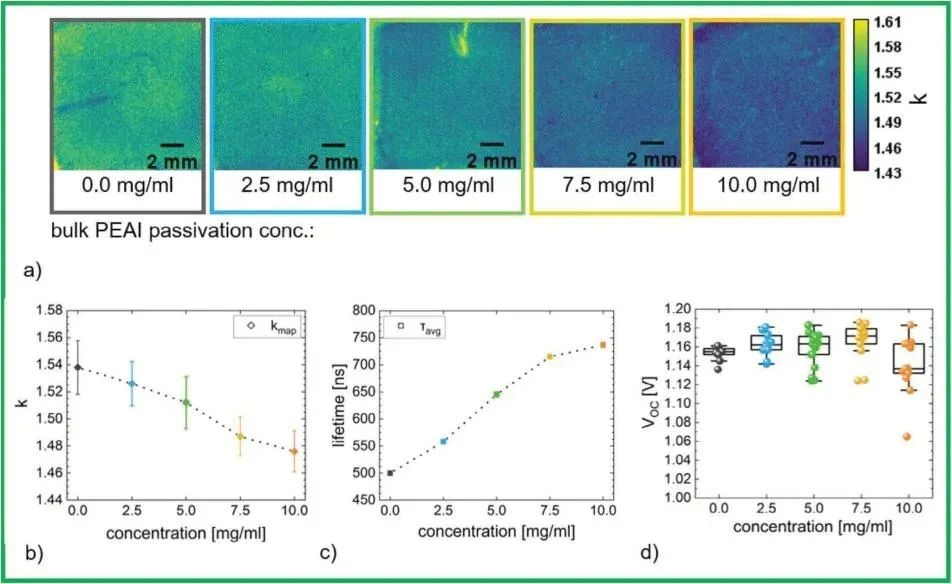

Optimization of passivation concentration (a-d) PEAI gradient experiment (c) TRPL evidence

Application of k imaging in optimization of PEAI bulk passivation concentration. As the PEAI concentration increases from 0 to 10 mg/ml, the k value shows a monotonically decreasing trend, but the solar cell Voc decreases after reaching a peak of 1.17 V at 7.5 mg/ml. TRPL testing shows that the carrier lifetime reaches 312 ns at 7.5 mg/ml, which is 75% higher than that of the unpassivated sample.

Further impedance analysis shows that although excessive PEAI continues to improve the bulk quality (k↓), it will introduce an insulating layer effect, resulting in an increase in series resistance and a decrease in FF. This reflects the unique value of k imaging - it can independently evaluate the passivation effect and avoid mutual coupling interference of the overall performance parameters of the solar cell.

The k parameter imaging technology developed in this study achieves accurate evaluation of the quality of perovskite films through power law analysis of light intensity-dependent photoluminescence (PL). Experiments have shown that this method has unique robustness to optical artifacts and can effectively diagnose interface engineering effects and optimize the passivation process window. In particular, the correlation between the k parameter and Voc variation (sensitivity 20mV) provides a reliable basis for real-time quality decision-making in the production line.